Replacing our Radiator Surge Tank- 2003 Freightliner XC

Odometer 77,861 miles

Trip Meter- 0 miles

Spoiler alert- This is a tech session, so if you’re looking for travel and adventure- skip this post and read the next 😊

I have used this platform before to talk about mechanical issues that have happened to our motorhome, and it has sometimes helped others that have the same issues. I have been the beneficiary of many blogs and online video how-tos. This is my way of paying back the universe.

|

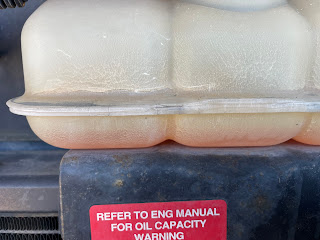

| Picture #1 Surge tank on top of radiator |

If you have a Freightliner XC chassis built around 2000 and have a caterpillar 3126 engine, you are familiar with this view of the rear engine compartment of your coach. The tank on top of the radiator is the surge (or overflow) container that stores coolant that expands when the engine heats up, and returns the coolant to the radiator when the engine cools down. Unfortunately the tank breaks down in sunlight and starts to crack, and crumble, and leak.

|

| Picture #2. Cracks in surge tank |

Here’s a closeup of what our tank looked like. The cracks have been there for several years now and that have finally cracked all the way through, allowing coolant to leak out. We did this repair ten years ago for what we thought would be the last time 😏.

It did occur to me at that time that I should do something to protect the tank from uv rays (sunlight), but I was convinced that sunlight didn’t really get that far into my engine bay. Well.. surprise! My naivety means that we get to do this again.

The new tank was available at the Freightliner dealer near me in Phoenix, AZ. The price at the time of this posting (2024) was $169.00. For owners of diesel pusher motor homes, getting to the engine usually means removing the bedding and the bed platform, and the engine covers.

The surge tank is held onto the radiator with four 9/16” bolts and nuts. And they pretty darned hard to get at.

|

| Picture #4 Four attachment bolts and nuts 9/16” |

|

| Picture #6. Removing Oil filler |

- Since I am right handed, I kneeled beside the bed pedestal/ engine cover on the passenger side, facing the rear. (picture #3 above)

- Reached in with my right hand, into the space created by the removal of the dipstick and oil fill.

- First I felt with fingertips to get a feel for where I had to get the ratchet on the bolt head. The bolt goes horizontally through the plastic tank mount then, through a hole in the vertical steel of the tank platform. (Picture #7 above). I am close to 6 foot tall and I can just barely reach this area with my right arm fully extended and head turned sideways and pressed tightly onto the top of the engine deck lid. One of the contortions I mentioned.

- Next I withdrew my hand and went back in, this time with a 1/4” drive ratchet and a 9/16” socket. To get the socket on the bolt you have to be nearly vertical with the ratchet (remember the webs on the plastic tank. The plastic webs also prevent your turning the ratchet in a very big arc (maybe 10 degrees of movement)

- Here you need an assistant on the outside to hold the nut. The bolt on my coach is so close to the sidewall of the engine compartment that I cannot get a box end wrench on it- so an open end wrench is what I used. The assistant can move the wrench up and down to back off the nut while you hold the ratchet on the other end- or you can do the reverse and see if you can turn the bolt with ratchet while the assistant holds. As you loosen the nut, the bolt could be pulled back enough to get the box end wrench on the nut if you want to stop to do this. It may prevent you from dropping the nut as it comes loose. With patience you can do this!

- The bolt goes through a flat metal strap the is the hanger for the oil fill tube below. (Picture #5) Your assistant may need to lift a little on this hanger strap to allow you to withdraw the bolt from the mount.

- Okay, if you got this far, congratulations! Only 3 bolts to go. Next, I tackled the bolt just forward of the first one, on the same side of the tank. Working from the bedroom side again (as you will for all of them) you’ll need two wrenches one to hold the nut and one to turn the bolt- hard, but not impossible.

- First I removed the filler cap and the overflow hose on the rear (exterior) side of tank

|

| Picture #11 Remove all hoses and the level sensor from old tank |

- Depending on how much coolant is left in your old tank and, where you want that to go, you may want to rig a catchment ( I did this) and remove the lower return hose on the bedroom side of the tank. (Outflow in picture above) I was able to get a plastic 1 gallon juice bottle in the fan area and tip the coolant (mostly) into the bottle. Unfortunately, you cannot simply insert a small hose and pump out the coolant (I tried this first) as the interior of the tank is a honey comb of plastic dividers. So the messy way, was the only way.

|

| Picture #12 Hose connection at inflow ports |

- Next I removed the two smaller hoses on the top of the tank. With the overflow hose removed, I could now pull the tank inwards to the engine bay and get pliers on the retainers and work the hoses off. I have no idea if the routing is important, (which hose to which port) so I marked one hose with red tape to get them oriented the same way on the new tank.

|

| Picture #13 Author has added clip nuts to tank mount |

|

| Picture #17 Re-install the dipstick tube and the oil fill tube |

Do you have the part number for the tank?

ReplyDelete310F/05-17750-002 TANK-SURGE,FLH,PLASTIC

Delete